Software development

Station monitoring

With Industry 4.0, it is very important to get process data easily accessible for better monitoring and improvement.

For existing installation using Siemens PLC for example, we can extract process data and to send them on database server. Then you can get accurate quantities, line stops... without any intermediate data keying and paper records.

Traceability

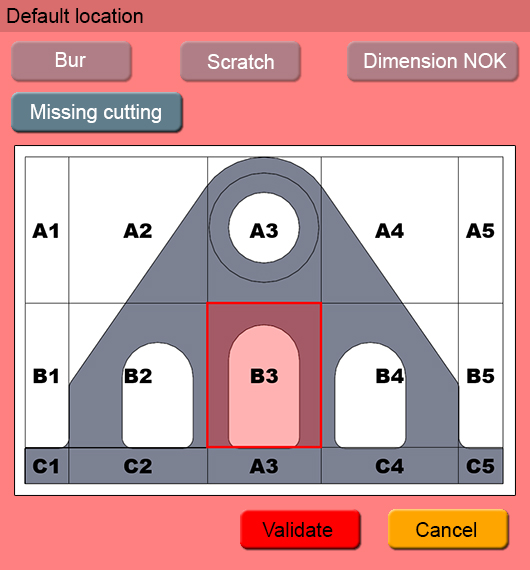

GR Engineering is providing complete traceability solutions, with records on MSSQL or MySQL. It can be manual/automatic code readers (like datamatrix, QR Code, barcode) on line stations to record component's serial numbers, associated with desktop or web software development to get operator's name, time, quality status, rejects codes and areas.

In our machines, we also give traceability solution with local or server data record, so you can easily monitor your production and get on live reaction like with SPC tools. Small applications allow to extract data (txt, csv, xls...) with multi criteria filters.

Process activities

We are providing solution (desktop or web application) in order to follow, record, monitor and report activities like:

- poka-yoke checking

- calibrations

- production measurements

- scrap management

- audits

- ...